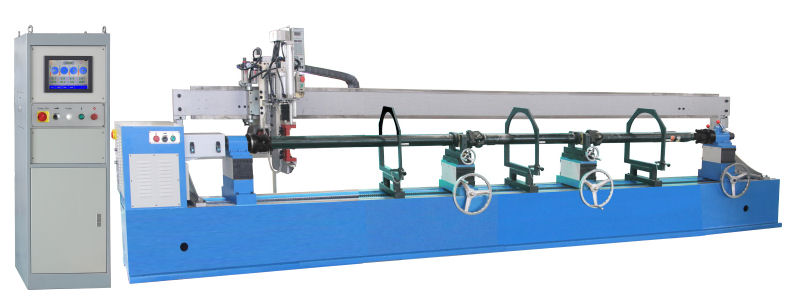

These machines have been designed and constructed with the operating habits and procedures of the industry needs in mind. It has set solid and reliable pedestals for stable damping and rigidity. The belt is more flexible to create ease of belting after loading the crankshafts. The measuring software has an auto memory feature allowing for the storage and recall of balancing test sequences and rotor calibration data.

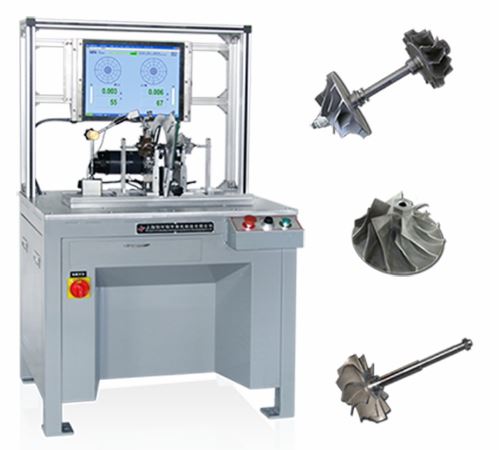

The belt-driving technology ensures accuracy unlike alternative direct drive systems. The Optoelectric scanning head allows for the scensing of different types of crankshafts and different positioning. With the auto-position function (optional add-on), the unbalance point or correction point will be precisely located and highlighted.

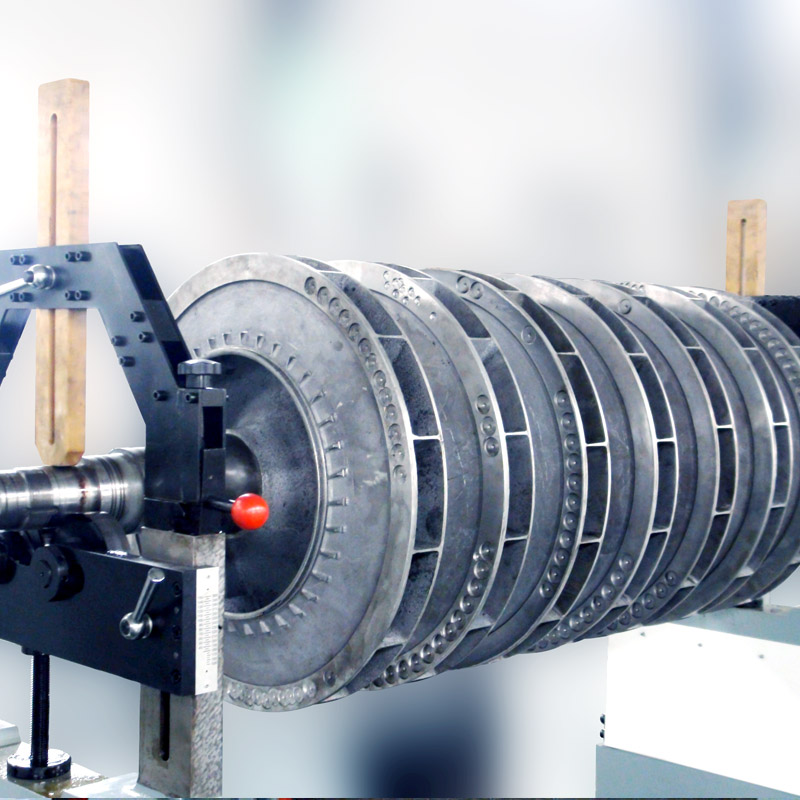

- Specially designed brackets transmit mechanical force with low vibration damping and high rigidity

- Durable and reliable sensors possess the signals into a filtered linear signal

- Permanent calibration brings high accuracy with the ability to accommodate large initial unbalances

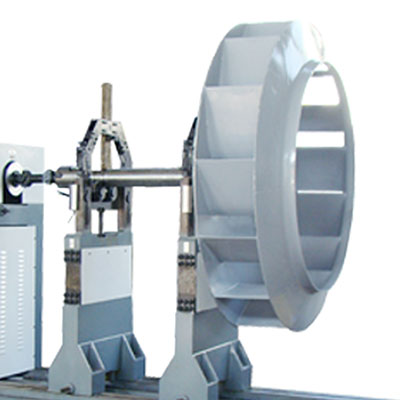

- Belt-driven offers high precision and easier operation

- Advanced electrical measuring system and user friendly interface

- Modular design offers a wide range of applications